Dismate PE (Plodia &Ephestia) is a powerful non-toxic mating disruption system used to combat food moths in food processing and manufacturing facilities. It is a proven system with real life experience over 17 years in manufacturing facilities across Europe. By reducing the likelihood of successful mating, Dismate PE rapidly and substantially decreases the resident population food moths such as Plodia and Ephestia species and prevents a subsequent population from becoming established. When applied as recommended, Dismate can permanently remove and prevent moth infestations in food processing and storage premises.

What is Dismate?

Dismate Video Tutorials

Dismate – Spanish

What is Dismate? – Spanish

How does it work? – Spanish

Dismate – Other Related Videos

EgonKulmsIng – Dismate

Dr Shakir Alzaidi presenting Dismate PE

What is Mating Disruption?

Lifecycles

Dismate PE works by releasing pheromones from strategically placed Dismate PE dispensers to disorient male moths. When a male moth detects the pheromone, he immediately begins to flutter around looking for the female, using up his energy and dying before he has the opportunity to mate. As female moths lay fewer and fewer eggs the longer they wait to mate, and any eggs that are produced are of poor quality, the resident moth population can be effectively and efficiently removed. The system then provides permanent protection from a further resident population developing.

Why use Dismate?

Almost every area where food is processed will have moths. Most areas will have some kind of monitoring system such as glue traps, funnel traps with a pheromone lure or a pheromone trap such as the Xlure RTU. Up until now the only treatments have been with the use of poisons either by gassing or by spraying. Today more and more companies in the food industry are moving away from poisons and demanding non-toxic solutions.

Dismate PE is a non toxic treatment for the food moths Plodia and Ephestia. The product was first used in the UK in 2001. A large breakfast cereal manufacturer decided they no longer wished to have poisons in their factory and their pest controller asked Russell IPM if there was an alternative. Russell IPM proposed Dismate and an 8 month trial was commenced. The trial proved such a success that a 10 year long term study was begun to gather the data for a product registration and we now have a Europe wide registration for Dismate PE.

Benefits

- A non-toxic, safe and effective, year-round system that disrupts mating without the use of harmful chemicals or fumigation

- A steady release of pheromones over three months

- The pheromones cause sensory overload in the male moth antennae and compete with pheromone plumes produced by female moths, making males unable to locate females for mating

- A preventative and curative solution without the need for downtime Specially designed to control the key moth species which affect the food industry

- The dispensers come in four distinctive primary colours, one for each season of the year, to serve as a reminder of when to change them

- Both the dispensers and cable ties are metal detectable

- The system is available with wall brackets or just cable ties for easy installation

How to use Dismate Solution?

Dismate dispensers are installed every 7 meters and changed every three months. It is very important this density is maintained. It is always better to install one more than one less. The pheromone in the dispenser evaporates in the air causing the male moths to be more active. The males become confused and excited and begin a so-called mating dance using up their limited energy and dying without mating. The females must wait longer to be mated and the longer she waits the fewer eggs she lays and the eggs that she does lay are of a poorer quality. The moth population is therefore reduced.

The monitoring system should be maintained and it is important to know that when Dismate is first installed it is possible that more moths are seen on the wing and also the catch in pheromone traps may increase. This phase can last from a few weeks to three or four months and every installation are likely to display this effect to greater or lesser degree. Following this a steady and sometimes dramatic decrease in moth activity will result. Dismate is not a substitute for good hygiene and it may be necessary to educate the end customer in hygiene before installing Dismate. Continue with the current monitoring system and keep honest accurate documentation. This will help to identify problem areas and indicate where extra actions are required. Finally, it is very, very, very important to install dispensers every 7 meters and maintain this density. Better one too many than one too few.

Continuing fall in moth counts

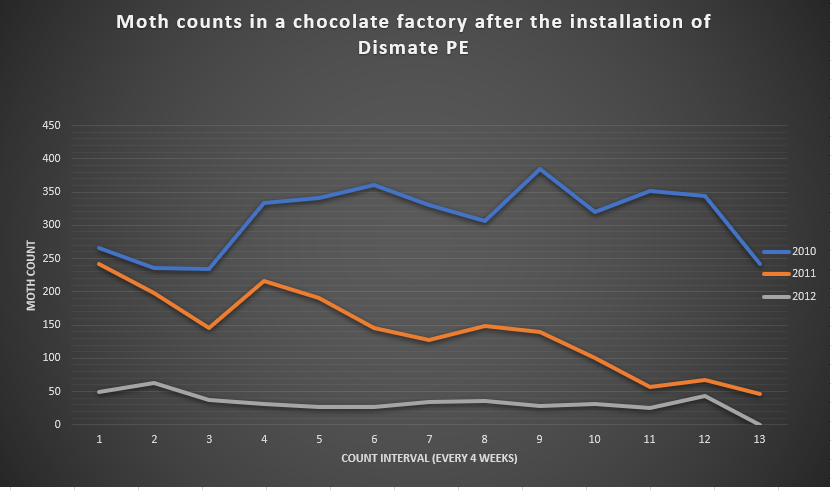

When Dismate was installed in a large chocolate factory dramatic results were seen.

Before Dismate was used the company would stop production every thirteen weeks and carry out a deep clean. Then two days of treatment with pesticides followed by a further deep clean to remove any pesticide residue. Not only was this procedure expensive but also caused a loss of sixteen days production annually.

During this time, they recorded over 4500 moths per year in the monitoring system. When they began with Dismate they stopped the poison treatments and the deep cleaning but continued with the routine daily cleaning. In the first year of Dismate use the moth counts fell to 450 per year. Last year the moth counts fell again to 113 moths and this year the counts have fallen to 4 per month. Similar results have been demonstrated in flour mills and bakeries also.

Third party information – Articles & Fact Sheets

Food industry moths always a problem and a challenge

Fest Management in the Food lndustry

Dismate PE – a safe food moth control system based on mating disruption without using chemical pesticides

Focus on Agriculture